Inspired by

nature

The process

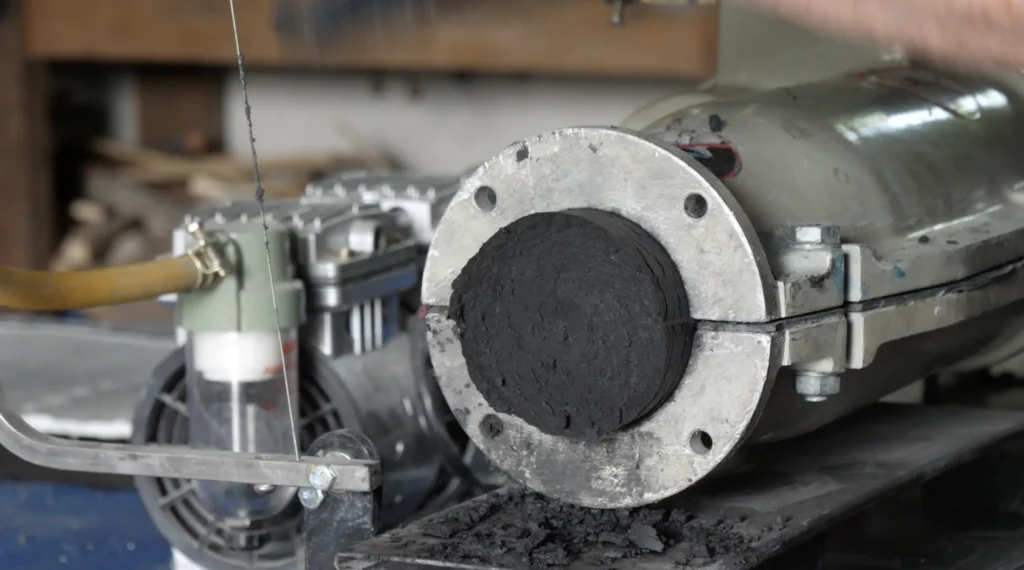

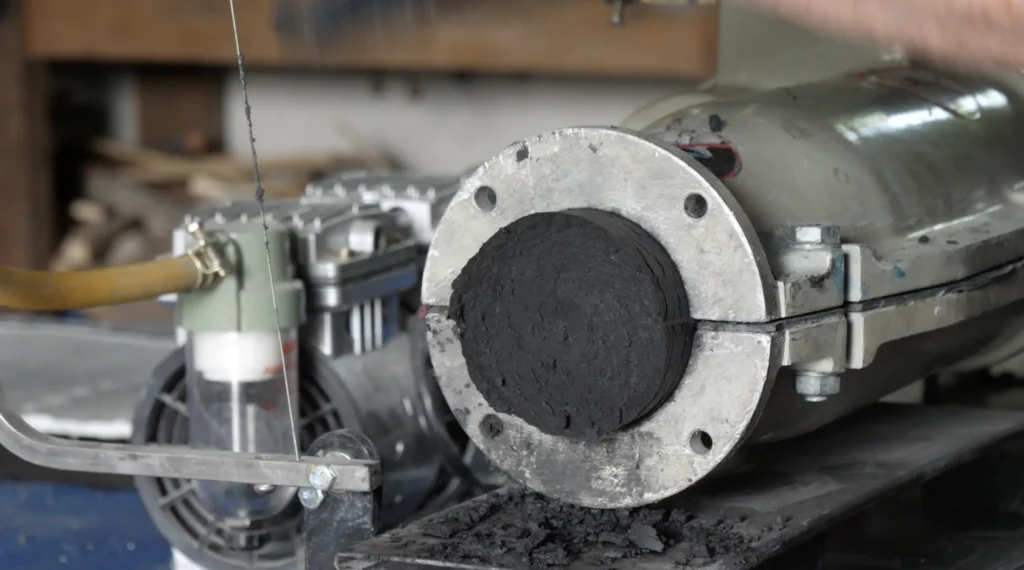

The Lithosynthesis© process

occurs in five detailed steps as outlined below.

It’s easy to set up and relies on components available anywhere in the world, making it a cost-effective and environmentally-friendly solution, since everything can be created using locally available resources.

Minéalithe is also committed to reinventing an age-old technology, using a gentle no-fry chemistry, where 95% of mineral components are used from natural sources. Their products are infinitely reusable and can be returned to nature at the end of their life cycle, without the need for treatment. This non-toxic solution is also fully recyclable.

2. Add natural mineral reagents and water (rainwater, sea water, even sugar water).

3. Addition of filler, which can be mineral, vegetable, waste, synthetic, etc.

4. Mixing of components using conventional equipment.

5. Obtaining a stone paste ready for extrusion, molding, manual or mechanical coating.

Those who tried to achieve through fire

what is done through water, and through heat

what is done through cold, have made a mistake.

Those who tried to achieve through fire what is done through water, and through heat what is done through cold, have made a mistake.

Bernard Palissy, 1580.

The fields

of applications

Decoration and arts and crafts

Minéalithe© can be cast in conventional silicone molds. Thanks to its exceptional reproduction fidelity, it is possible to produce museum, decorative or ornamental elements (ornamentation, modenature, furniture, fireplaces, jewelry, statues, etc.). The mastery of a vanished technology of low-temperature, self-glazing sand earthenware opens up unprecedented prospects for an original art form.

Art and History

Minéalithe©’s ability to produce “soft stones” with the same chemical composition as many natural rocks, using technology within the reach of ancient civilizations, makes it possible to create megaliths that are impossible to carve and transport. Art history will be strengthened by an identical replica.

Medical

Lithosynthesis©, with its mechanism close to that of the natural formation of “stones” in the human body (teeth, bones, kidney stones, etc.), makes it possible to design bone prostheses using the same components, and in 3D printing.

Aerospace and Automotive

Collaborations have already been initiated to enable design offices to work together on innovative applications, or the creation of specific lithosynthesized tools or novel technical ceramics.

Recycling industry

Minéalithe© can encapsulate and inert the most technical and harmful materials, whether metallic, mineral, chemical or even plant-based.

Building

Minéalithe© can be molded, cast, extruded, printed or coated. It gives the resulting product uncommon mechanical and environmental characteristics, equivalent or superior to most cements and concretes, with the added bonus of incomparable “STONE” aesthetics.

The fields

of applications

Minéalithe© can be molded, cast, extruded, printed or coated. It gives the resulting product uncommon mechanical and environmental characteristics, equivalent or superior to most cements and concretes, with the added bonus of incomparable “STONE” aesthetics.

Minéalithe© can encapsulate and inert the most technical and harmful materials, whether metallic, mineral, chemical or even plant-based.

Collaborations have already been initiated to enable design offices to work together on innovative applications, or the creation of specific lithosynthesized tools or novel technical ceramics.

Lithosynthesis©, with its mechanism close to that of the natural formation of “stones” in the human body (teeth, bones, kidney stones, etc.), makes it possible to design bone prostheses using the same components, and in 3D printing.

Minéalithe© can be cast in conventional silicone molds. Thanks to its exceptional reproduction fidelity, it is possible to produce museum, decorative or ornamental elements (ornamentation, modenature, furniture, fireplaces, jewelry, statues, etc.). The mastery of a vanished technology of low-temperature, self-glazing sand earthenware opens up unprecedented prospects for an original art form.

Minéalithe©’s ability to produce “soft stones” with the same chemical composition as many natural rocks, using technology within the reach of ancient civilizations, makes it possible to create megaliths that are impossible to carve and transport. Art history will be strengthened by an identical replica.

Contact

us

Contact us

02240 Sissy France

+33 06 43 15 80 47

minealithe@wanadoo.fr

Rue Georges Charpark

02100 Saint-Quentin

+33 03 23 62 72 35

+33 06 43 15 80 47