The science

of mineral

creation inspired

by nature.

Discover how Minéalithe

has reimagined the formation

of minerals at low temperatures.

Our history

and our mission.

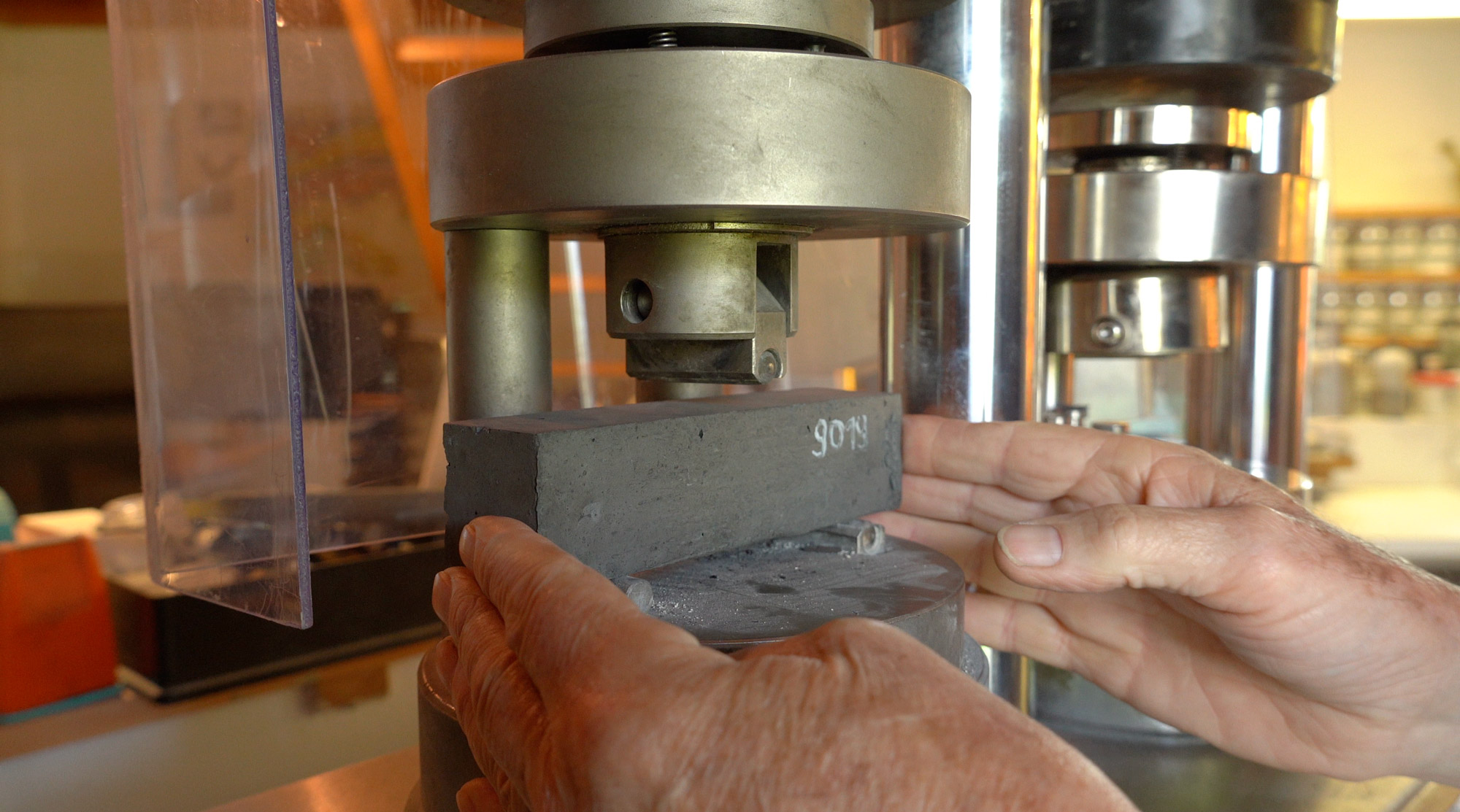

The human body can produce teeth or kidney stones at a temperature of 37°C in an aqueous environment. This was the starting point for our research in 2005, which focused on the creation of low-temperature minerals in liquid solutions.

The challenge was to reproduce the natural formation process of certain low-temperature rocks using mineral salts, but in an accelerated way, without the need to calcinate components, which would have involved significant energy consumption.

After 17 years of research, 15,000 test tubes and collaborations with renowned geologists and chemists, Minéalithe© led to the creation of Lithosynthèse© in 2023.

5 key points of Minéalithe

5 key points of Minéalithe

The Minéalithe© process is unlike any other. It’s not just another binder, glue, cement, geopolymer or sol-gel. We call it Lithosynthesis©, an intimate chemical reaction between its natural components, which recreates the stone and rock-forming processes in accelerated form. This new science is an original and remarkable technological breakthrough.

Unlike many “traditional” building materials such as cement, plaster, synthetic plaster or resin, Minéalithe© products have a lifespan probably equal to that of rock. Their chemical composition corresponds to that of stones found in nature.

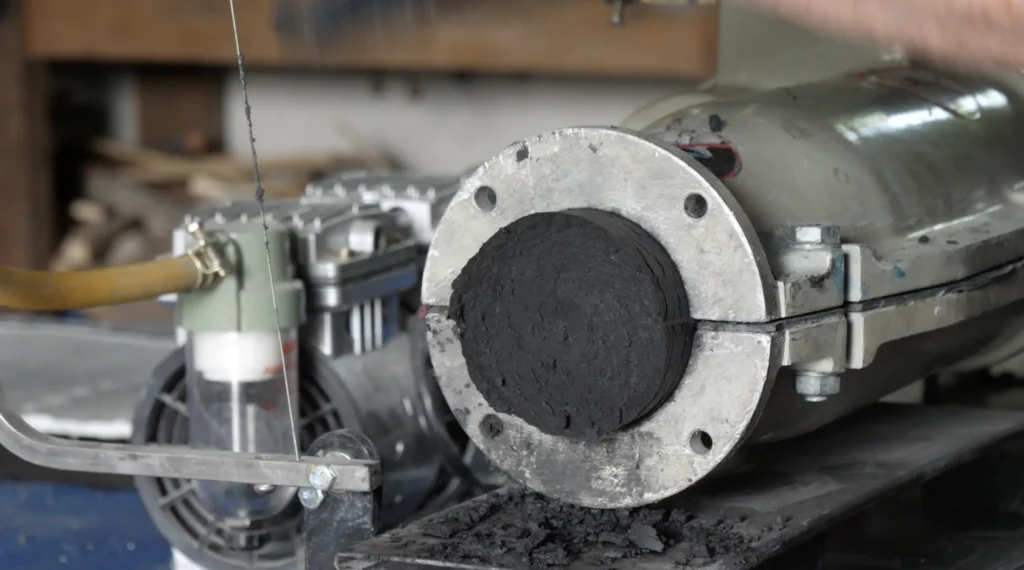

The Minéalithe© process does not require heavy technology or a large energy source.

Most applications are carried out at room temperature or at low baking temperatures.

If the composition of the filler permits, a family of specific ceramics fired at wood-fired temperatures (850°) can be derived, offering remarkable properties. (The resulting ceramic product can withstand temperatures in excess of 1500°, in the case of refractory products).

One of the major advantages of the Minéalithe© process is that the products resulting from this technology are infinitely recyclable! As they are literally stones, they can be returned to the earth or used as a “filler” to create a new product. It’s as simple as that!

In the Minéalithe© process, we certify that all the components used are of natural origin and available worldwide, and that they have not been calcined at high temperatures.

This is soft chemistry involving only natural chemical reactions and not aided by the addition of petrochemical products or hydraulic binders.

Multiple applications

There is

multiple

applications

The properties of Lithysynthèses® are many and specific.

The properties of Lithosynthesis® are many and specific.

Building

Can be molded, cast, extruded, printed or coated.

Recycling industry

Enables the most technical materials to be encapsulated and inerted

Aerospace and automotive

Find innovative applications.

Medical

Conceptualize the manufacture of bone prostheses using 3D printing.

Decoration and arts and crafts

Produce museum, decorative or ornamental items.

Art and history

Adaptable to all shapes and sizes.

100% Ecological

In the Minéalithe© process, we certify that all the components used are of natural origin and available worldwide, and that they have not been calcined at high temperatures.

This is soft chemistry involving only natural chemical reactions and not aided by the addition of petrochemical products or hydraulic binders.

Total recycling

One of the major advantages of the Minéalithe© process is that the products resulting from this technology are infinitely recyclable! As they are literally stones, they can be returned to the earth or used as a “filler” to create a new product. It’s as simple as that!

Energy efficiency

The Minéalithe© process does not require heavy technology or a large energy source.

Most applications are carried out at room temperature or at low baking temperatures.

If the composition of the filler permits, a family of specific ceramics fired at wood-fired temperatures (850°) can be derived, offering remarkable properties. (The resulting ceramic product can withstand temperatures in excess of 1500°, in the case of refractory products).

Durability

Unlike many “traditional” building materials such as cement, plaster, synthetic plaster or resin, Minéalithe© products have a lifespan probably equal to that of rock. Their chemical composition corresponds to that of stones found in nature.

Technological Breakthrough

The Minéalithe© process is unlike any other. It’s not just another binder, glue, cement, geopolymer or sol-gel. We call it Lithosynthesis©, an intimate chemical reaction between its natural components, which recreates the stone and rock-forming processes in accelerated form.

Multiple

applications

The properties of lythosynthesisare diverse and specific:

Building

Can be molded, cast, extruded, printed or coated.Recycling industry

Enables encapsulation and inerting the most technical materialsAerospace and automotive

Find innovative applications.Medical

Conceptualize manufacturing processes of 3D-printed bone prostheses.Decoration and arts and crafts

Producing museum pieces, decorative items, or ornamental elements.Art and history

Adaptable to all shapes and sizes.Our services

Taking your specific needs into account, we find the best formulation to meet your specifications.

Minéalithe© also offers consultancy services, guiding you through the development of new production lines utilizing the Minéalithe© process.

Minéalithe© manufactures and markets small series of finished products (cobblestones, pebbles, technical beads, prototypes or sculptures) as well as products for your building sites or production plants. It also specializes in the manufacture of highly technical products, such as high- and low-temperature tools for leading-edge sectors.

Taking into account your technical, environmental, aesthetic and economic issues, we find the best formulation to meet your specifications.

Minéalithe© plans to market its “inducer” in small packages to a network of licensed craftsmen, after training on our premises.

We offer a full range of innovative services. Our services include research into customized formulations to meet your technical, environmental, aesthetic and economic needs. We also manufacture and market finished products, such as cobblestones, pebbles, technical beads, prototypes and sculptures, suitable for a variety of applications. We also offer professional support for the development of new production lines using their revolutionary process.

Exhibitions

and awards

Exhibitions and awards

Our work has been recognized

Exhibition at VIVA TECHNOLOGY

Paris 2019

Grand-Prix Geste d'Or

Paris 2020

Exhibition at the Salon du Patrimoine

Paris 2021

Winner of the European METABUILDING competition

2022

Grand-Prix du ré-emploi, BIM World trade show.

Paris 2023

Contact

us

Contact us

02240 Sissy France

+33 06 43 15 80 47

minealithe@wanadoo.fr

Rue Georges Charpark

02100 Saint-Quentin

+33 03 23 62 72 35

+33 06 43 15 80 47